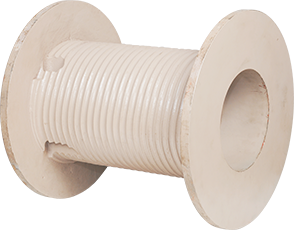

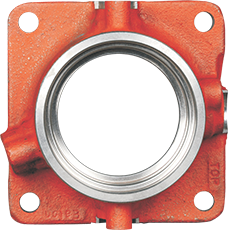

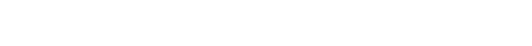

Foundry Division

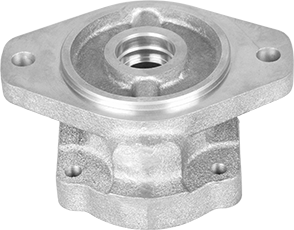

- 1250 KW Tri Track Induction Furnace, with Present Melting Capacity of 11 00 MT I Month.

- A Semi automated sand plant for green sand moulding process with sand preparation capacity of 30 MT I Hour.

- A fully equipped testing lab.

- In house casting simulation facility.

- In House facility for special sand process like silicate.

- No bake and shell mould.

- In House core making facility.

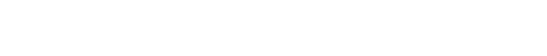

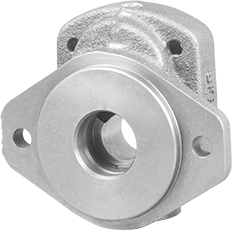

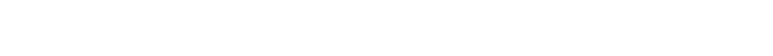

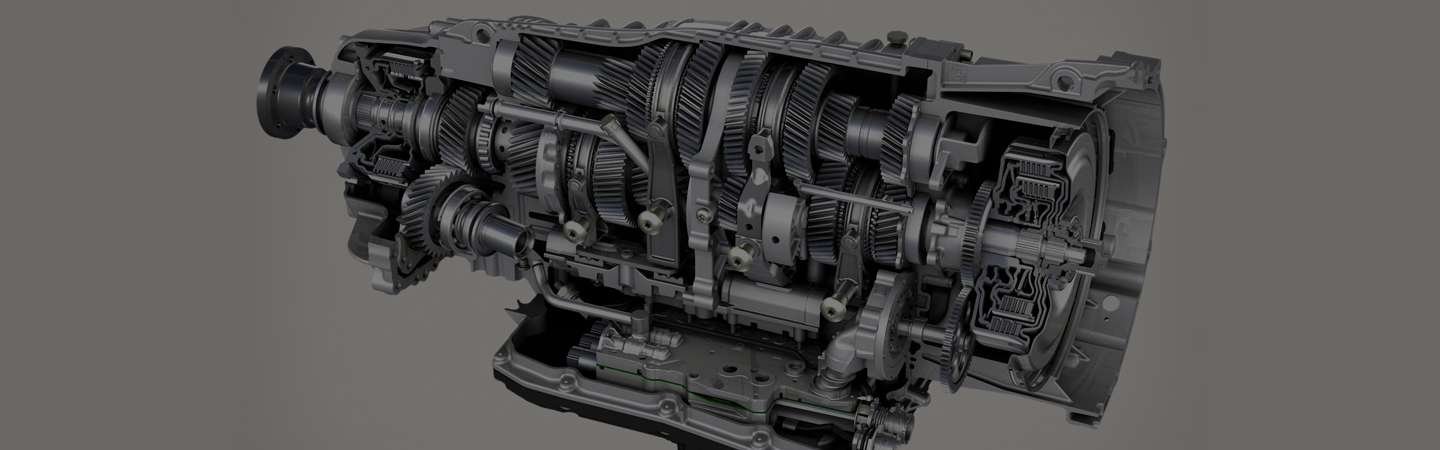

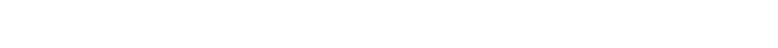

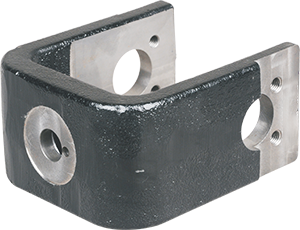

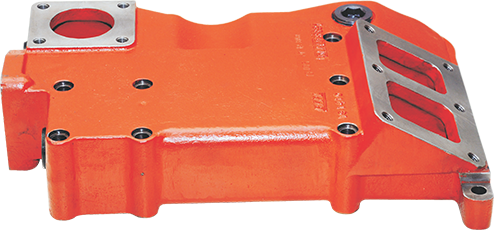

Machining Devision

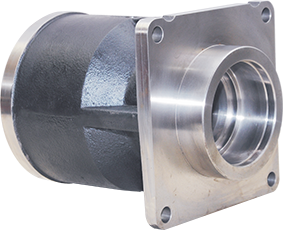

- Machine centres (VMC).

- Vertical Turn Mill Centre (VTM)

- CNC turning centres which production capacity range from 60 chucking to 200 chucking capacity.

- Retro fit CNC turning centres.

- Conventional Lathe machine.

- Milling Machine.

- Broaching machines.

- Drilling machines with SPM.

- Hot wash cleaning machine for Millipore.

- Salt spray testing Machine.

- All the adequate inspection equipment's are in place.

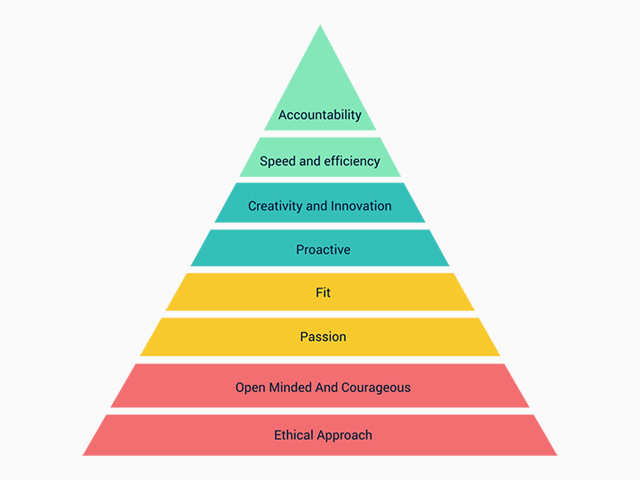

Strengths

- Small to Large batches Sizes Production Flexibility.

- All Molding Process Under one roof.

- Practice TOC and LEAN for overall Business Growth.

- Adequate Infrastructure and in house Manufacture facilities.

- Faster Response time.

- Dedicated development team.

- Strong Sub contracting base.

- Sound financials.

- 30,000 Sq.ft. land available for expansion.

- full fledge in house testing facility.

Awards

Clients